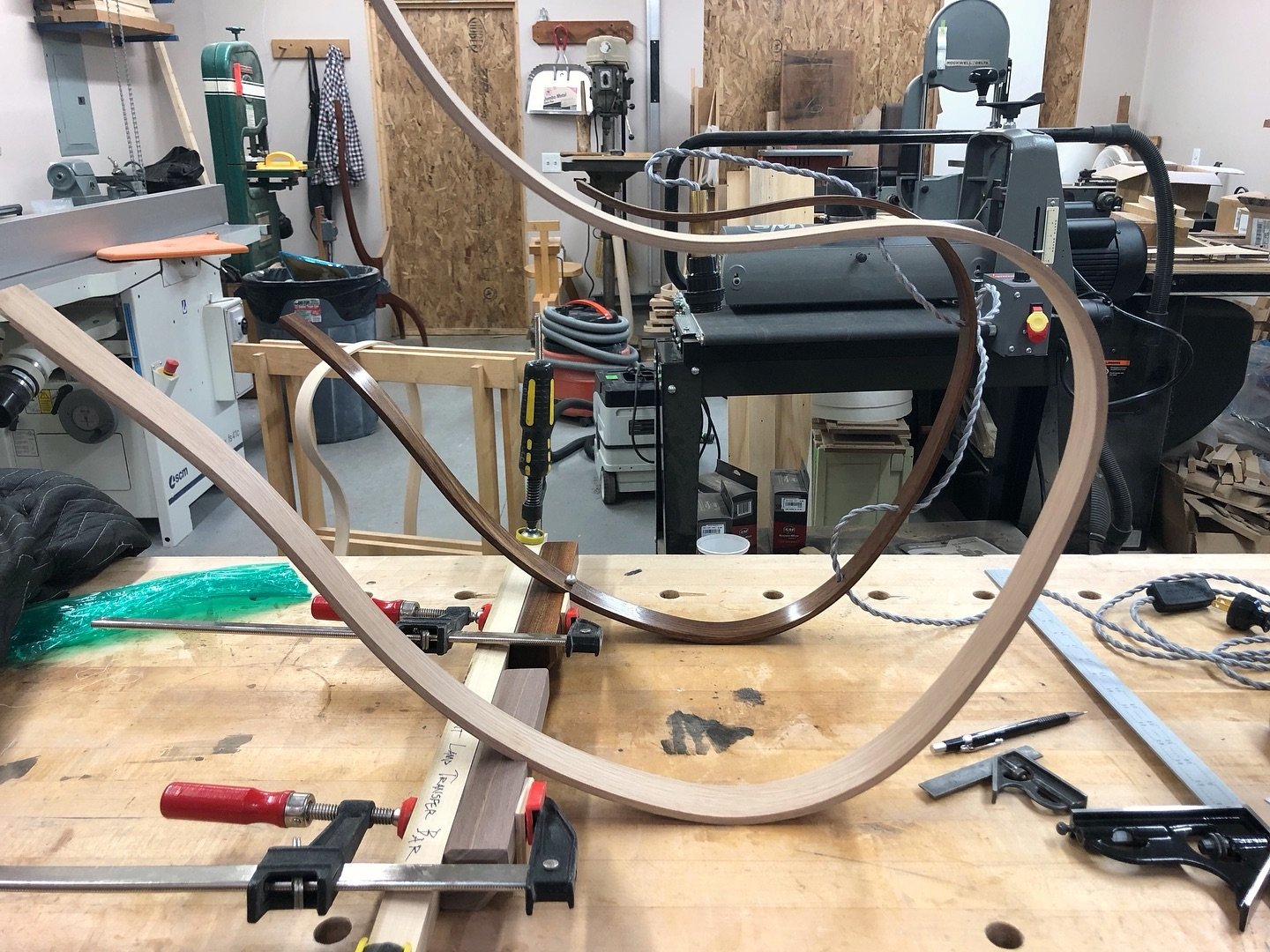

The guides and adjustment on my Powermatic 141 bandsaw are solid and predictable.

Yeah, they don’t make them like they used to, right? This statement seems easy to apply to power tools on today’s market. It’s an odd thing to reconcile if you think about it. Why aren’t tools makers able to build a good product today and it seems like there are a ton of good options on the used tool market from 50 years ago or more. Maybe the antique tools we see are the market have just withstood the test of time. And maybe there was just as much junk on the market 50 years ago but what we see today is what has held up.

I have two bandsaws that are both 40 or 50 years old. Both are 14” and one is a Delta/Rockwell and the other a Powermatic. I’ve had the Delta/Rockwell for almost 10 years now and never did too much to it to get it running. It’s a solid machine but not extraordinary. Its big strength are the guides. They are easy to adjust and once adjusted hold true. Two months ago, a client called me and asked if I’d be interested in an old Powermatic bandsaw saw. He was moving and didn’t want to deal with the hassle of moving it. I’ve been taking it apart and replacing the bearings and tires. I really love how well everything is made. The saw is overbuilt for its size and capacity. I do think that is why it has held up so well. The adjustments are simple and rock-solid.

This summer I was at Center for Furniture Craftsmanship for a class and sawed veneer for a set of doors for the first time. It was not the first time I had used shop sawn veneer on a set of doors, but it was the first time I did it well and did it correctly. I was really excited with how the doors came out and wanted to do more shop sawn veneer work. A project came up that veneer was the best choice, a drop leaf table with internal slides. The shop I work out of had recently gotten a Laguna BX18 bandsaw. I was excited to try making shop sawn veneer with this saw. I had not used the saw very much before trying to saw veneer with it. I went deep into the saw when I installed a ½” Wood Slicer blade on it to have a try at resawing. The first step before putting in a blade for resawing was to loosen and move all of the guides away from the blade. I had a lot of confusion when I did this. The guides on the Laguna are… let’s just say they don’t inspire a lot of confidence. I was able to loosen them up and move them anyway I wanted. I what I mean is out of square with the blade. To square them up you just… guess, maybe. Not sure what the right answer is here. I hope I can eyeball square with 100% accuracy. So, to move on, getting the guides exactly where I wanted them to support the blade was not satisfying. After setting things up and giving it a try the guides looked out. I readjusted things and then again didn’t get good results. I suppose I could have kept trying, but I couldn’t really make the guides work better. I just don’t like the choice they made with the way they work at all.

What’s going on with the Laguna? As I’ve been working on the Powermatic bandsaw the adjustments and guides are really well done. Every bit of what guides and supports the blade does the opposite of what it does on the Laguna. Is it because the Laguna is new, and the Powermatic is old? Seems a little simple of a conclusion to come to. With the Laguna it feels a bit like a cad drawing. You can almost see the parts rendered in aluminum on screen. A reinvention of the wheel. With the Powermatic it feels more familiar. There are recognizable systems that work.

I’ve read a few reviews of the Laguna online and they all talk about the bandsaw being there to satisfy a middle price point. The main question I have is the process in making a saw like this today. Is the saw built from the top down? The company leaders and planners deciding what price points their line of saws need to hit and then the designers getting the problem of how to make an 18” bandsaw that can be sold for $2000? That would make sense as to why some of the compromises that were made.

Fifty years ago, that method of producing a saw was probably not perfected. Who knows. This is merely one man’s meditation on this modern world but I’m happy to have the bandsaws I do.